I have been fortunate to enjoy - great dinners in the kitchen's of these two ladies. So, I gladly helped Adeline with her new dream kitchen when she asked me.

AFTER

|

In our Kitchens, our families experience the best conversations, learn family values, and share great family recipes- adapting healthy eating habits - to fuel our best achievements. We share histories of our lives, life lessons, laugh and cry in our kitchen. A lot of time is spent with our most important friends and family there. This young lady asked me to change the colour of her beloved kitchen from Golden Oak to one she was dreaming of for a long time. One that would reflect her long desired change.

Before

In order to prepare for this lengthy job, Hours are spent removing doors to transport, wrapping them, stripping them of wax and grease with TSP.

The multiple coats of Lacquer are mechanically sanded down by hand, going in the same direction as the grain, and all raised panel edges and coves need to be cleaned out and stripped.

The new primer and paint goes on top of the lacquer, after all the doors are degreased and deglossed. The deglosssing is best done manually with sandpaper and other abrasives after the degreasing is completed. This ensures optimal bind for the new paint which will not peel off.

This picture below illustrates the degreasing dewaxing process, with the removal of those rubber bumpers, by a sharpened putty knife to use as a scraper.

The cloth is filled with Trisodium Phosphate to remove all of the grease, oil and waxes. Skipping this step means that the oils will simply be pushed around the surface by sandpaper and abrasives and not removed, causing the paint to delaminate over time.

The glass inserts in doors needs to be removed gently on the workbench. And all hardware on doors are removed, followed by taping up all of the drawers to prevent over spray.

The glass inserts in doors needs to be removed gently on the workbench. And all hardware on doors are removed, followed by taping up all of the drawers to prevent over spray.

The garage door for the bread box also needs to be dismantled for spraying, and Note that I am holding up 3 fingers to remind myself the spring is wound 3 times for reassembly - thereby properly setting tension for lift assist on the garage door.

All doors are degreased. With 35 pieces, the degreasing process followed by sanding does take quite a few hours. All Surfaces, even the coves and cracks need to be manually abraded.

This is what the doors look like with the paint completed at 9 coats of paint after the primer is applied and the final paint is sprayed.

The bridging has now all dissappeared.

Some of the wood grain is purposely left to show, to allow the doors to have the solid wood look and feel.

Here is a better picture of the wood grain.

And another wood grain picture.

The hardware is installed back on the doors and the doors are placed back on the cabinets.

That breadbox was completely dismantled and sprayed offsite, and then reinstalled back between the upper cabinets and the lower counter top. A very tricky and finite job to ensure it goes back tight and in place. All of the caulking also needed to be removed and replaced as well.

The drawers still show their hardwood oak character after spraying is completed.

No Brush marks at all on these drawers and doors, they look as good as brand new custom sprayed oak.

The overall look is a much updated new looking kitchen at a fraction of the cost of replacing your cabinets.

The Crown molding all is done onsite matching the sheen of the doors as well.

Thank you Adeline for letting me be the expert on your Kitchen transformation. I truly enjoyed the experience, and I am glad that you love your new kitchen.

Before

|

This particular Kitchen has been restored to Benjamin Moore Cloud White  |

In order to prepare for this lengthy job, Hours are spent removing doors to transport, wrapping them, stripping them of wax and grease with TSP.

The multiple coats of Lacquer are mechanically sanded down by hand, going in the same direction as the grain, and all raised panel edges and coves need to be cleaned out and stripped.

The new primer and paint goes on top of the lacquer, after all the doors are degreased and deglossed. The deglosssing is best done manually with sandpaper and other abrasives after the degreasing is completed. This ensures optimal bind for the new paint which will not peel off.

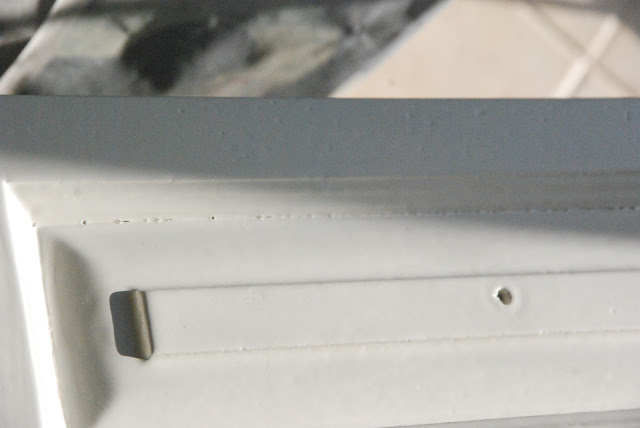

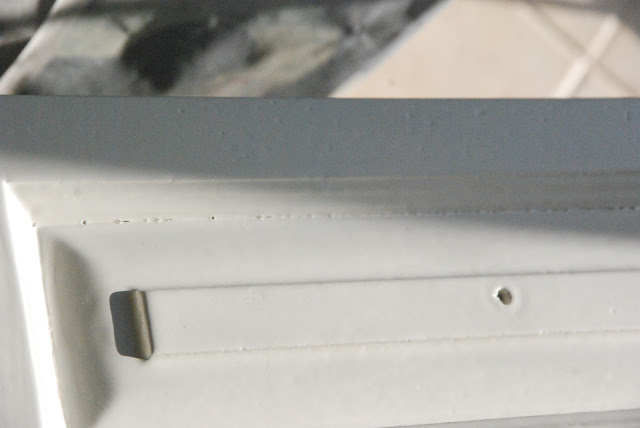

This picture below illustrates the degreasing dewaxing process, with the removal of those rubber bumpers, by a sharpened putty knife to use as a scraper.

The cloth is filled with Trisodium Phosphate to remove all of the grease, oil and waxes. Skipping this step means that the oils will simply be pushed around the surface by sandpaper and abrasives and not removed, causing the paint to delaminate over time.

The glass inserts in doors needs to be removed gently on the workbench. And all hardware on doors are removed, followed by taping up all of the drawers to prevent over spray.

The glass inserts in doors needs to be removed gently on the workbench. And all hardware on doors are removed, followed by taping up all of the drawers to prevent over spray.

The garage door for the bread box also needs to be dismantled for spraying, and Note that I am holding up 3 fingers to remind myself the spring is wound 3 times for reassembly - thereby properly setting tension for lift assist on the garage door.

All doors are degreased. With 35 pieces, the degreasing process followed by sanding does take quite a few hours. All Surfaces, even the coves and cracks need to be manually abraded.

The challenge with painting wood panelled doors is the crack between the frame and the floating panel. Wood expands and contracts and that crack always has movement. You will always get hairline cracks there, and they are part of the natural patina of a painted wood door. As i say " the cracks are free, enjoy them." There is no getting around it. You can see the door here with the first coat of primer that i am using called STIX.

Paint applied on that crack also starts bridging, (seen in the corner of the picture below) which are fingers of paint that also makes the surfaces look inconsistent. The whole crack needs to be filled to look consistent. In this case there are 9, YES 9 coats of paint to complete the bridging.

The drawers below show the bridging still in place after 5 coats of primer, and the pinholes in the grain still need to be covered in as well. Thin coats of primer and paint are always necessary for a professional looking job.

This is what the doors look like with the paint completed at 9 coats of paint after the primer is applied and the final paint is sprayed.

The bridging has now all dissappeared.

Some of the wood grain is purposely left to show, to allow the doors to have the solid wood look and feel.

Here is a better picture of the wood grain.

And another wood grain picture.

Next the crown molding and all gables in the kitchen are completed by hand onsite with a roller and brush. I have secret techniques to make them look like they are sprayed even though they are not.

The hardware is installed back on the doors and the doors are placed back on the cabinets.

The drawers still show their hardwood oak character after spraying is completed.

No Brush marks at all on these drawers and doors, they look as good as brand new custom sprayed oak.

The overall look is a much updated new looking kitchen at a fraction of the cost of replacing your cabinets.

The Crown molding all is done onsite matching the sheen of the doors as well.

Thank you Adeline for letting me be the expert on your Kitchen transformation. I truly enjoyed the experience, and I am glad that you love your new kitchen.

Comments

Post a Comment